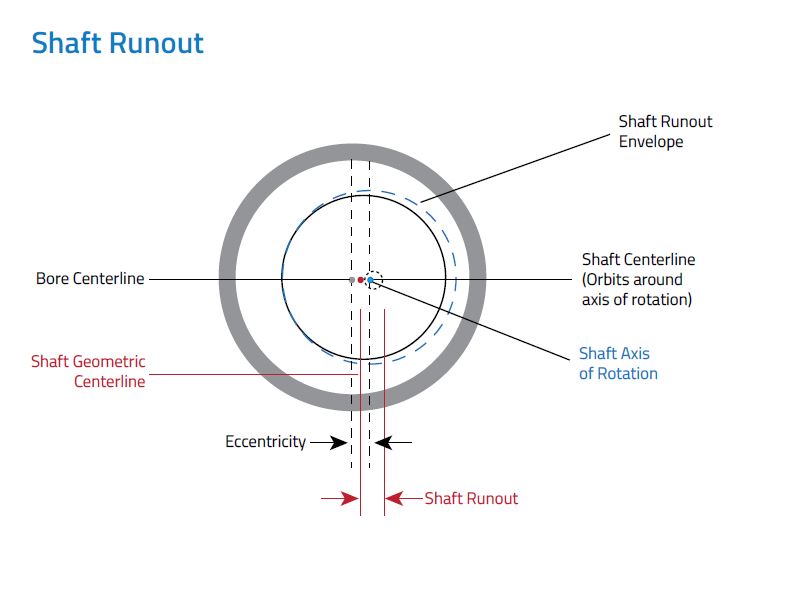

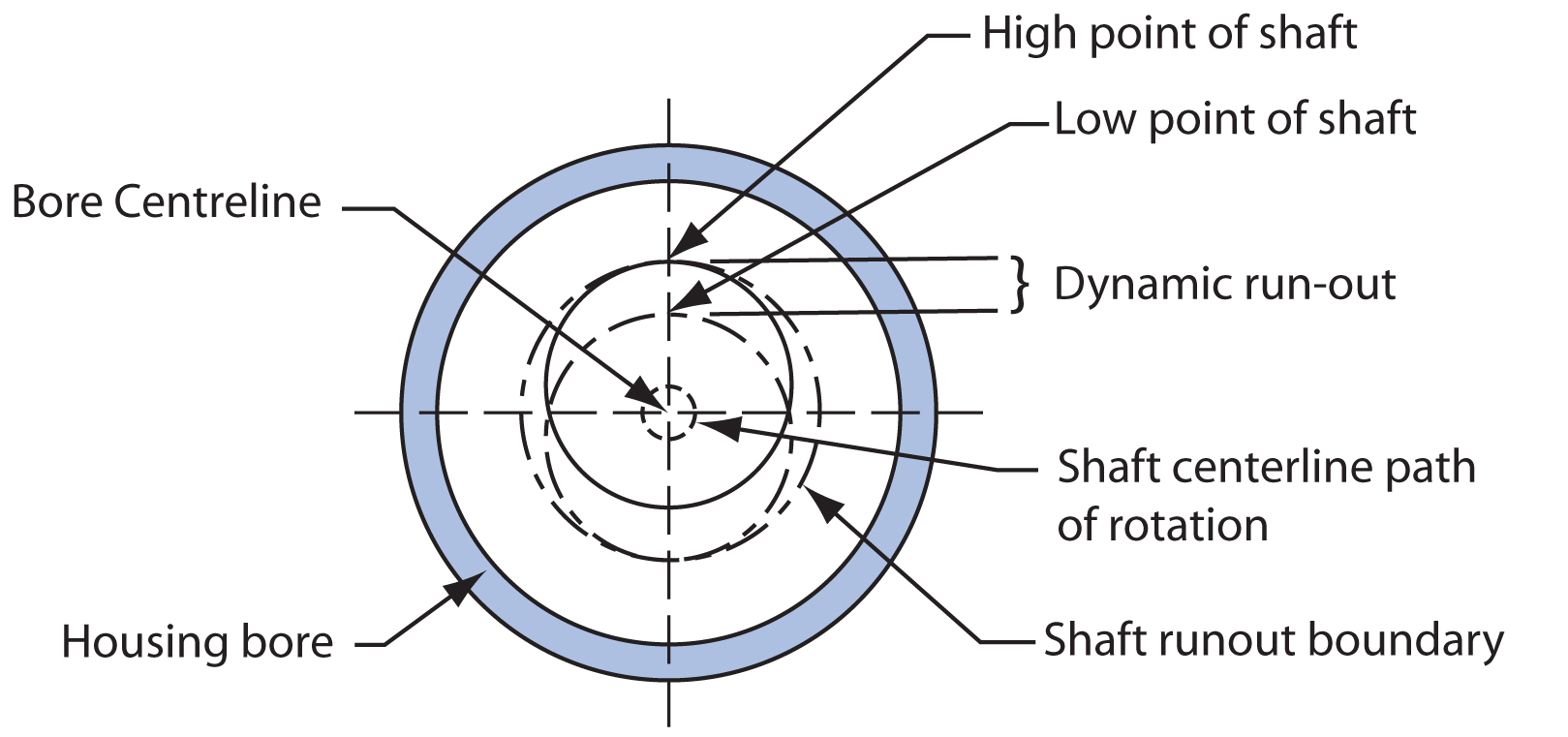

Coupling or Shaft Runout. On rotating machinery, runout is defined as the degree to which a shaft or coupling deviates from true circular rotation. Every shaft or coupling has a center or rotation, or centerline. Any stray from concentricity is considered runout. If runout is severe, it can cause many problems with equipment, such as: Runout.. Run-out or run-out is an inaccuracy of rotating mechanical systems, specifically that the tool or shaft does not rotate exactly in line with the main axis. F.

How to Check Brake Rotor RunOut Remmen Brakes

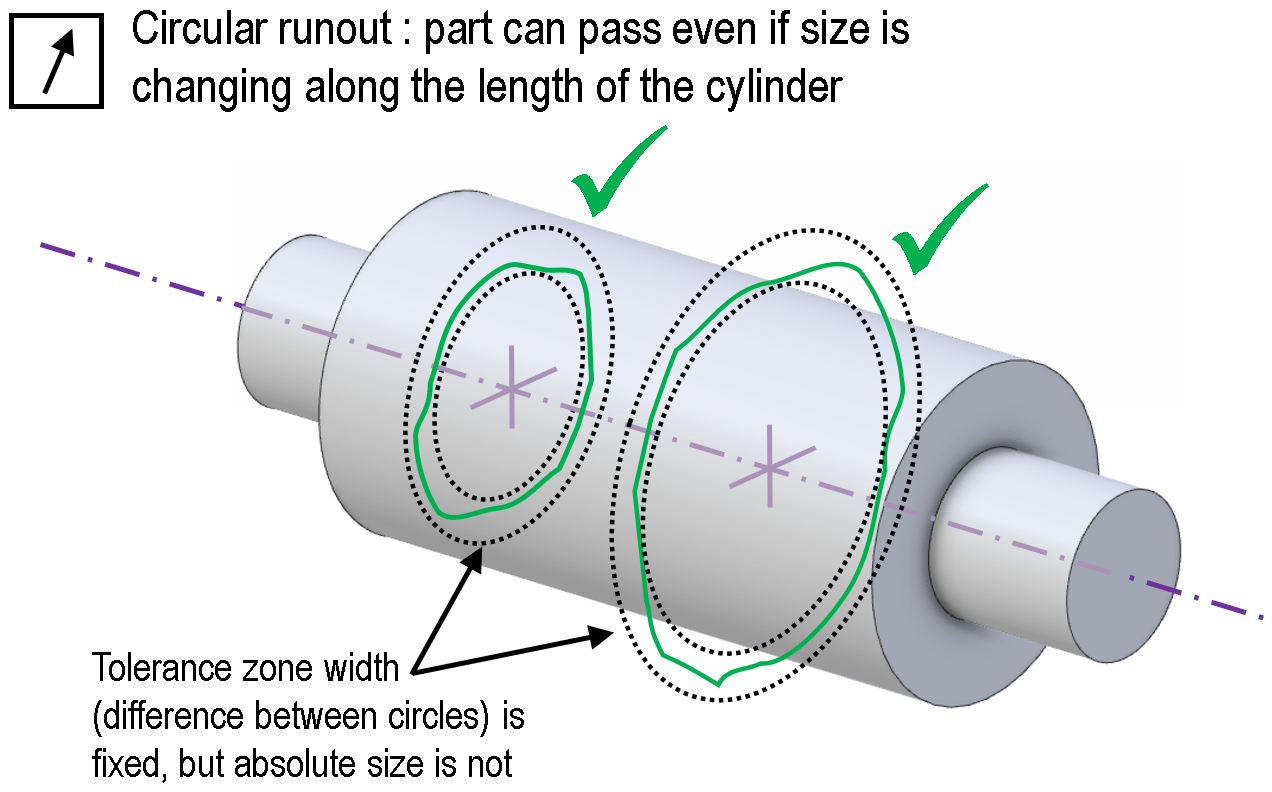

Circular Runout in GD&T Geometric Dimension and Control

Practical GD&T Circular Runout Measurement Basic Concepts Redlux

C5 Z06 Transmission T56 Output Shaft Runout YouTube

Shaft Run out correction YouTube

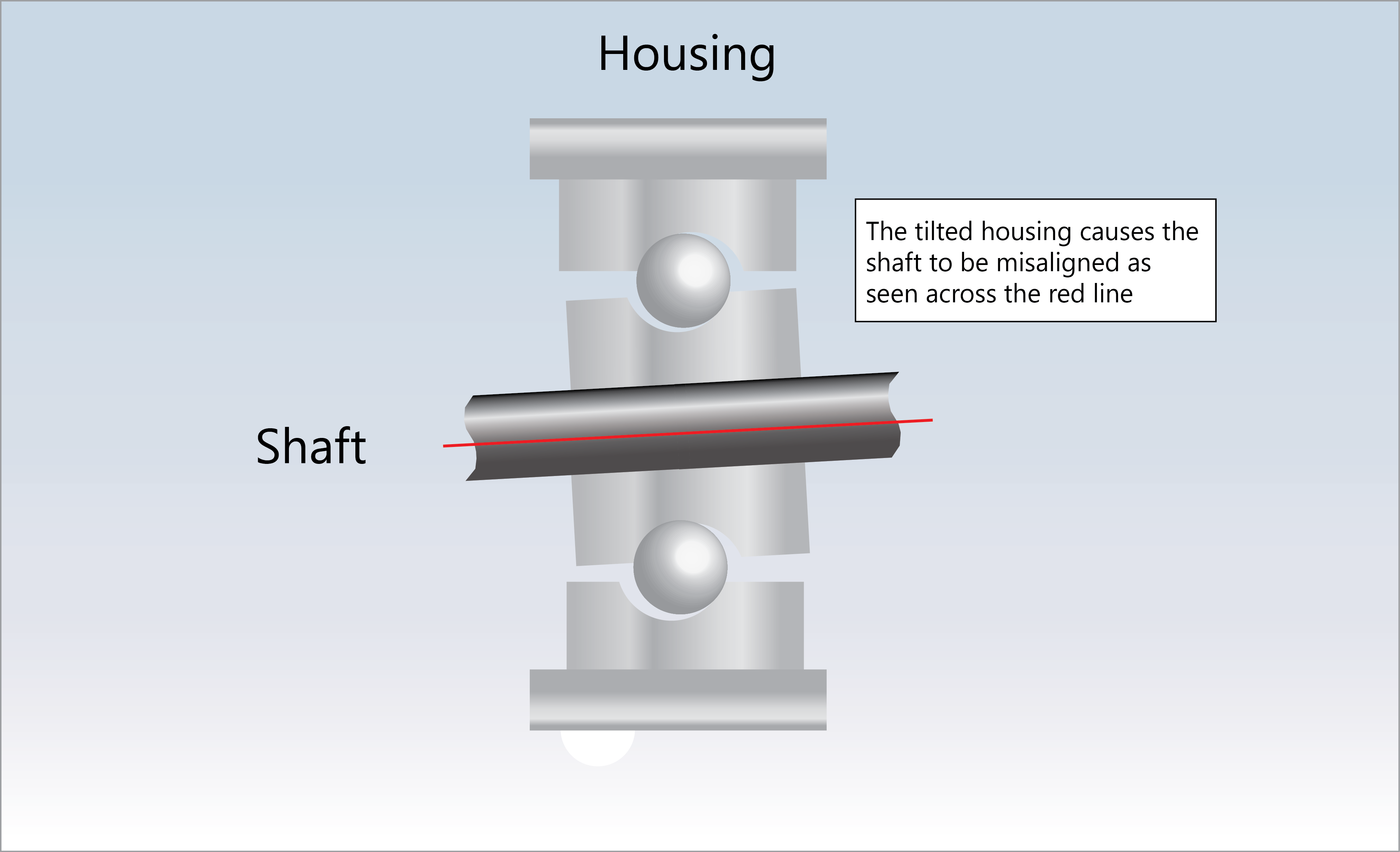

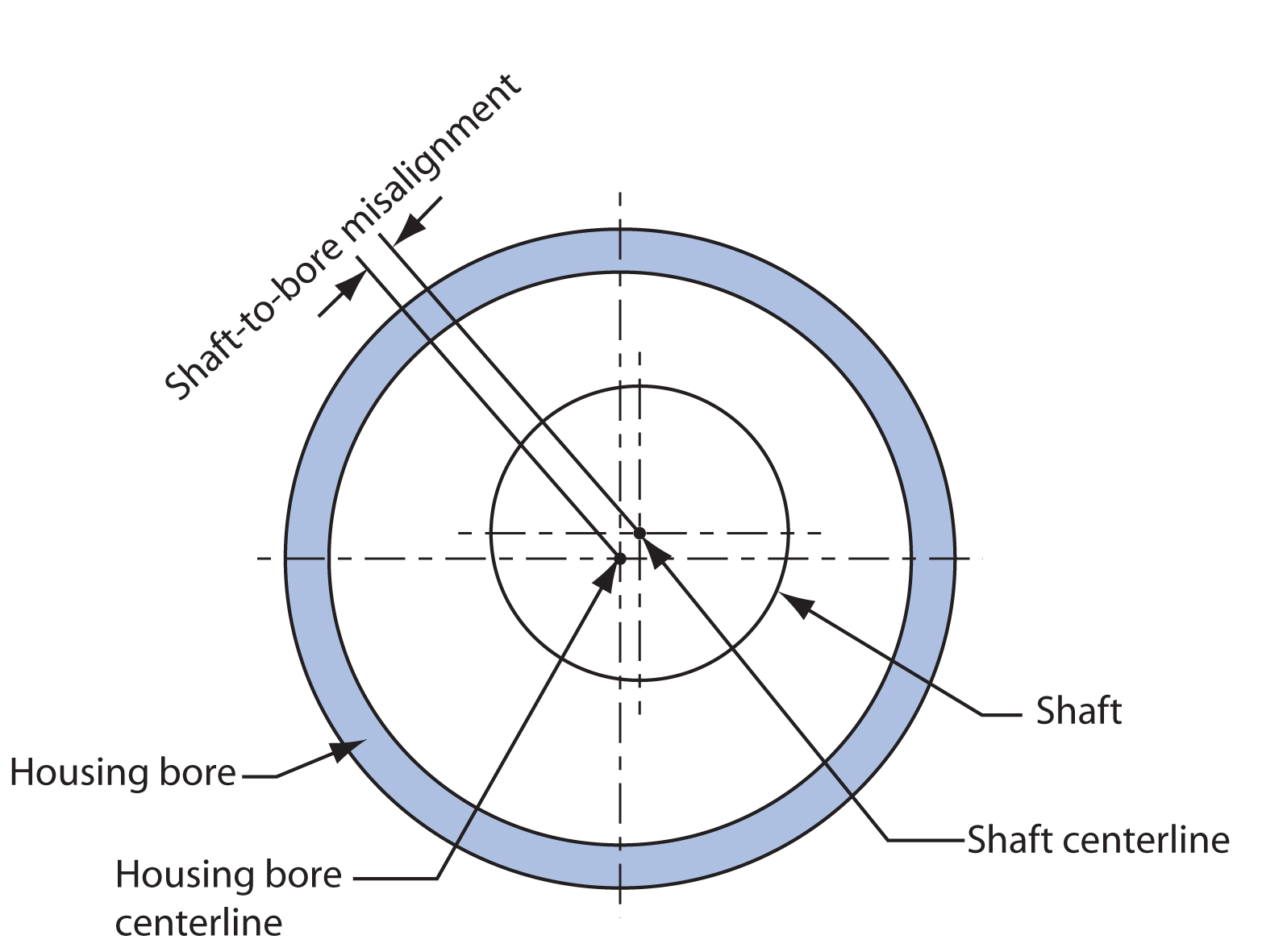

Understanding Shaft and Housing Alignment & Fits (to Prevent Bearing Failure)

Practical GD&T Total Runout Measurement Basic Concepts Redlux

Lion Precision’s Application Note To Improve Shaft Runout Measurement

Shaft run out YouTube

Difference between axial total runout and perpendicularity Drafting Standards, GD&T

How to measure Axle Shaft Runout YouTube

Technician Measuring Shaft Runout by Dial Gauge Stock Photo Image of industrial, machine

PTFE Rotary Seals Housing, Pressure and Shaft RunOut

Runout Vs. Total Runout What is the Core Difference?

Design of the Shaft Daemar Inc

Shaft runout and alignment (with english subtitles) YouTube

motor shaft runout YouTube

How to measure crankshaft runout YouTube

Design of the Shaft Daemar Inc

Measuring Shaft Runout Atlas/Clausing 4800 Lathe YouTube

Runout is a critical concept in precision machining that affects the quality, functionality, and lifespan of machined parts. Understanding the different aspects of runout, including GD&T runout, runout symbols, and common causes, is crucial for producing high-quality machined parts. Implementing proper procedures and using high-quality.. Attach the base to one of the lathe weighs and place the tip of the indicator perpendicular to the inside wall of the morse taper. 2. Rotate the lathe by hand and watch the indicator needle. 3. Stop the rotation at the lowest reading and set the dial to “0”. 4. Rotate the lathe until the needle reads its highest. 5.